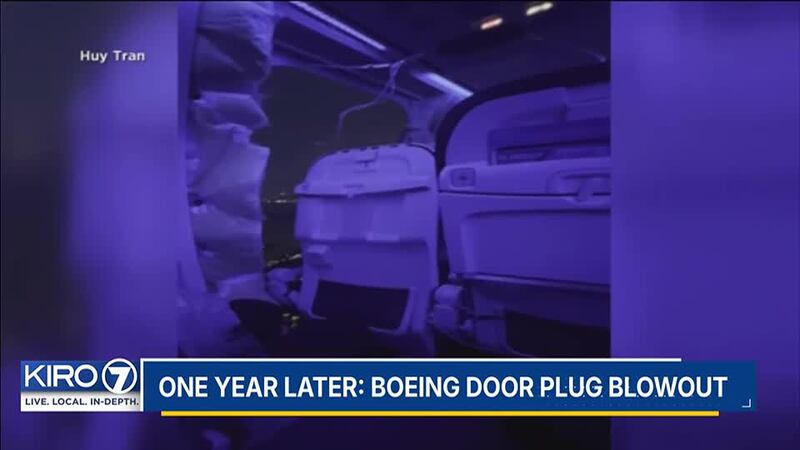

SEATTLE, Wash. — Sunday marks one year since an Alaska Airlines flight from Portland was forced to make an emergency landing after a door plug blew out mid-flight. The plane was a Boeing 737 Max 9.

“The oxygen masks come down, and I’m like, ‘this completely feels like a movie’,” recalls passenger Andrew Chhur.

He says it sounded like an explosion on the flight. It was a moment he says he thought might be his last. Chhur reached for his phone to say his goodbyes.

“What I thought would be, last messages to friends and family, just telling them, you know, ‘hey, something happened on this plane, not sure if I’m going to make it,” says Chhur.

Fellow passengers shared in that fear.

“It’s only by the grace of God and ten minutes that I’m still here,” says Garrett Cunningham.

That January 5th flight was the start of a turbulent year for Boeing.

“What’s it going to take for Boeing to get its act together?,” asks attorney Mark Lindquist. “They’ve suffered lawsuits, they’ve been criminally prosecuted, and their stock prices plummeted.”

Lindquist represents 34 clients, including Chhur, suing the aerospace giant for their experience on that flight. The filing claims that ‘the Max 9 aircraft was unreasonably dangerous and defective.’

“For lack of better words, this shouldn’t fly for a company like Boeing,” says Chhur.

Lindquist calls the door plug blowout yet another example of Boeing’s negligence. He also represents families who lost loved ones in the deadly airline crashes in Ethiopia in 2019 and Indonesia in 2018. Both planes were Boeing-made.

“After 346, people died in the two Max 8 crashes, Boeing put out a list of things they’re going to do to fix the problems and change the culture,” says Lindquist. “That didn’t happen. Now they have a new list out of changes they’re going to make. And at this point, a lot of us are skeptical.”

A spokesperson with Boeing declined multiple requests for an interview with KIRO 7.

In a statement, the company outlined a list of action items they say they’ve have implemented over the past year. They include things like: ‘new random quality audits’, ‘strengthened training for mechanics and quality inspectors,’ and ‘significantly reduced defects in 737 fuselage assembly at Spirit AeroSystems by increasing inspection points at build locations’.

“There’s no room for error in manufacturing an airplane,” says Lindquist. “Lives depend upon the quality of that aircraft.”

©2025 Cox Media Group